PLC Programming Using RS Logix 500: Diagnostics & Troubleshooting

The book series “PLC Programming Using RS Logix 500”, provides a guided, step-by-step approach to learning how to write ladder logic programs. Ladder programs are one of the principle types of control programming used in today’s manufacturing and industrial environments.

Diagnostics & Troubleshooting is the third book in this series, and explains the methods and tools that are available for quickly isolating problems in equipment controlled by SLC-500 or MicroLogix processors. Some of the topics included in Book 3 include:

- Status File Data

- Clearing “Minor” and “Major” faults

- Enabling and using forces.

- Performing Online Editing

- Creating and using Fault Routines

- Using the Multi-point Monitor & Custom Data Monitor

- Using the Histogram Tool

- Using the Find All and the Search and Replace functions

These are among the many topics detailed in Diagnostics & Troubleshooting. This third book; together with the companion books in this series, focuses on the goal of helping you achieve proficiency and mastery in the field of automation control programming. The topics and methods detailed here will aid you in maneuvering through program routines to isolate a problem area, whether it resides in the processor, the program instructions, within an I/O module, or with device outside the PLC.

Here is an excerpt from the section on using the S2 Status File :

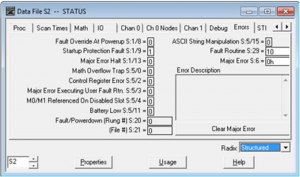

S2 Errors Tab:

Next is probably the most important Status file tab to access and understand; the “Errors” tab information. The “Errors” box shows several of the S:5 “minor error” bits that can cause bit S:1/13 to set – causing a “major error”.

Several of the S:5 bits (0-7), when set to “1”, will also set the S:1/13 “Major Error Halt”, at the end of the scan cycle. In this instance a “major” fault will occur, taking the processor out of “run” mode and requiring you to clear the fault before equipment can be restarted. Whenever this happens, a “major error” hexadecimal code is put into the “S:6” data field which references a specific problem area.

These S:6 hex codes differentiate between “Power Up”, “Going to Run”, “Run”, “User Program Instruction”, and “I/O” errors. A comprehensive listing of these error codes and their meaning is located in the Rockwell publication: 1747-RM001G-EN-P, and also the RS Logix 500 Instruction Set Manual, so I’ll not cover them here. However, it is important to know where to access this information. You should then be able to make necessary corrections to clear a fault condition, and hopefully prevent it from recurring. Here is an example I recently encountered, where I was able to use a “major error” code to find and correct a recurrent problem.